Why So Quiet?

New Fluid Technology Pty Ltd have invented a new principal of operation for pumps. The principle "Solid Body Vorticity" (SBV) can be applied to all pumps. Thus SBV is similar for example to the "Otto cycle" principle being applied to all internal combustion engines regardless of their size. We (NFT) design and build only prototypes for various applications for customers in the pump industry. For this we recieve an agreed royalty for every pump manufactured. Supa-Stelth are the most simple pumps possible. We have done away with the diffusers, volutes and even the "cutwaters" that are an integral component of all other centrifugal pumps and essential for their pressure and efficiency. The problem is these diffusers are the source of almost all of the noise and so eliminating these parts is the main reason our sound levels are so low in comparison.

So that we do not lose the efficiency those diffusers impart to conventional pumps we minimise the main cause of pump efficiency losses which is the water's momentum changes through the pump, sometimes called acceleration head. Please refer to the "PUMP HANDBOOK" ISBN is 978-0-07-146044-6. This is achieved 1; by our unique pump body and 2; our unique impeller.

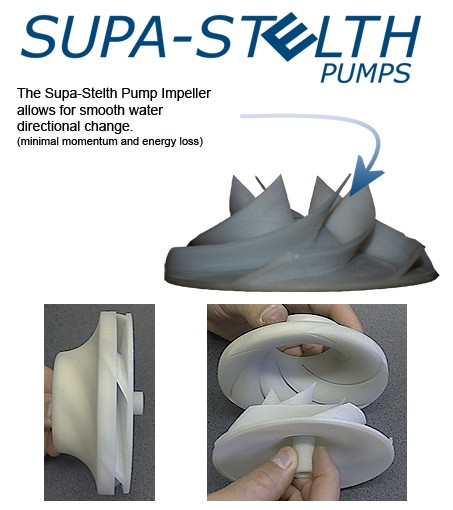

We Began with an Improved Impeller design

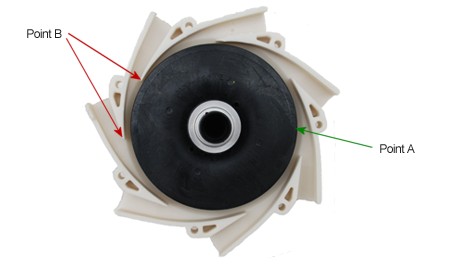

Comparing our impeller and a conventional pump impeller you will notice a big difference.

Our patented impeller manufacturing method enables a quality, scientifically designed impeller which allows the water to accelerate through the inlet to undergo smooth direction and momentum change before leaving the periphery. Conversely, with a conventional impeller, water gets drawn in and abruptly turns 90 degrees and then exits the periphery after uneven acceleration, thus reducing its efficiency. Also in conventional pumps that have to employ diffusers to get their efficiency the water hits the diffuser inlets at around 18+metres / second generating major noise.

Our patented impeller allows for a far smoother passage for the water to flow.

It has a "cork screw" type curve rather than a "right angle" turn as in the conventional pool pump impellers.

This once again reduces shock, noise and increases overall efficiency.

In conventional pumps water leaves the circumference of the impeller apertures (POINT A) at approx 18 metres / second and strikes (POINT B) the internal leading edges of the diffuser.

This results in the high noise level of ALL other pumps!

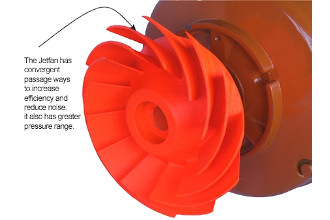

The JETFAN motor cooling fan

Jet FanAfter redesigning the pump impeller for minimum noise and maximum efficiency we set about doing the same for the cooling fan, another major source of noise especially in pool & spa pumps. The result is the JETFAN cooling fan unique to Supa-Stelth.

Our World Patented Jetfan is the world's most quiet and high pressure fan! This helps to further reduce the overall pump noise.

The fan noise alone on many conventional pumps are greater than the combined pump / fan noise from an equivalent Supa-Stelth Pump!

Yes, the JETFAN is unique in that it can deliver the highest airflows at the highest pressures compared to any other mixed flow fan known. So advanced is jetfan no other company on earth even knows (because the blades overlap at the hub) even how to mass manufacture it.